The company is located in Wenzhou, since 1998 we introduced the advanced technology from German, has more than 20 years of factory history. We specialize in producing all kinds of plastic zippers and related machines.We have dozens of new high-output plastic production lines, thousands of molds.

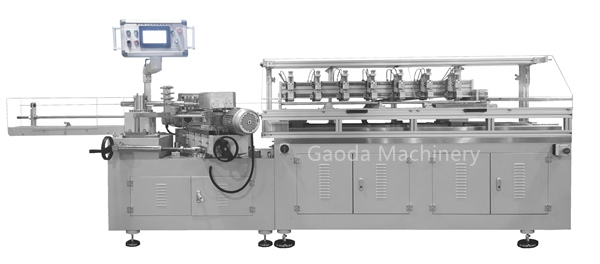

New 7 Cutting Knife Model Paper Straw Machine

1. 7 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder travel when changing different diameter mould.

2. 3 sets servo motor for cutting system moving left & right, supporting roller and cutting knifes.

3. Automatic paper roll connecting function bracket.

4. Glue heating and recycle function glue station.

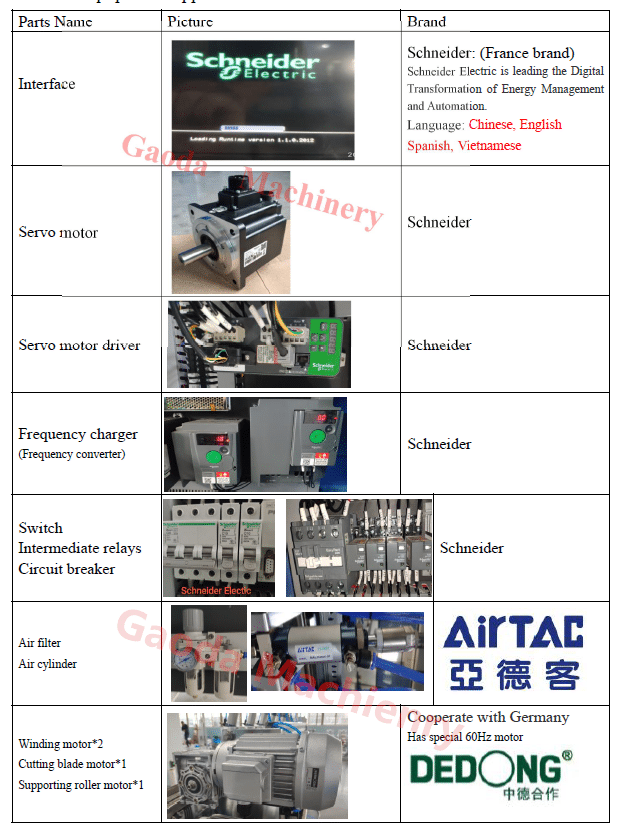

5. Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency charger.

6. High and lower voltage equipment separated distribution for more safety concern.

1. Working Principle and short introduction:

Winding different layers paper strip into paper tube with glue.

Multi-cutting knife system, by servo tracking, cut paper tube into small piece of paper drinking straws.FLA( Full load amp): 13.5A

Advantage of New 7 Cutting Knife Model Paper Straw Machine: GDM7-1DX:

1.7 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder travel when changing different diameter mould.

2.3 sets servo motor for cutting system moving left & right, supporting roller and cutting knifes.

3.Automatic paper roll connecting function bracket.

4.Glue heating and recycle function glue station.

5.Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency charger.

6.High and lower voltage equipment separated distribution for more safety concern.

S.N |

6 cutting knife |

New 7 cutting knife |

Sub-model |

GDM6-1 |

GDM7-1DX |

Cutting blade |

6 |

7 |

How many straws per cutting |

5 |

6 |

Max paper tube length |

1050 mm |

1260 mm |

Min paper tube length |

120 mm |

|

Max speed |

60 m/min(output speed) |

|

Stable speed |

30-50 m/min |

45-75 m/min |

Model

GDM7-1DX

Technical Parameter

Main Parts

Electric power

380V/ 3phase/ 50Hz

PLC

PanKong

Electric consumption

4.5-6.5Kw/h

Control screen

Schneider, 3 sets

FLA

13.5A

Control program

GD-XJ2.0

Speed

0-80m/min

Paper tube out put speed

Servo motor

Schneider

Paper layer

2-4层

Servo motor driver

Schneider

Straw Diameter

5--13mm (out diameter)

4.3--12.3 (inner diameter)

Frequency charger

Schneider

Max thickness

0.6mm-single side

High-voltage switch

Schneider

Min thickness

0.2mm-single side

Relay

Schneider

Straw length

110--1260mm

Distance between 2 blades

Signal sensor

Omron

Cutting method

7 knife, pneumatic

Encoder

Omron

Glue method

Single & double face

Pneumatic cylinder

AIRTAC

Length control

Encoder

Bearing

HRB

Speed control

Servo tracking

Attached equipment/function

Operator

1 person

Paper connecting function

Have

Mandrel fixing

Screw clamp

Dust & protection cover

Have

Synchronism control

Servo belt

Winding roller cover

Have

Winding belt tension control

Hand wheel

Cutting knife cover

Have

Belt angle control

Hand wheel

Pull force tension sensor

Have

Lubrication

Lubrication grease

Auxiliary air tank

Have

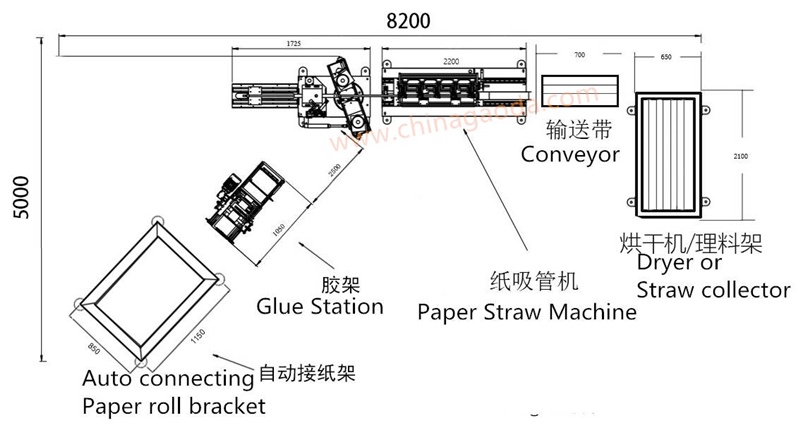

Dimension and Weight

Constant rewinding force

Have

Main part dimension

3850×1200×1600mm

Mould

Anti-vibration roller

Have

Land area dimension

9000×2500×1900mm

Glue recycle pump

Have

Winding roller diameter

195mm

Attached parts

Winding roller height

100mm

Paper Straw mould

3 sets

Weight

1350 KG

Cutting blades

14 pcs

Winding belt

15 pcs

Tool box

Have

2. Paper straw making mechanism

Winding & control unit and Multi-knife cutting system

Adopted man-machine control interface, touch screen parameters setting, easy for operating. Controlled by encoder, driven by servomotor. Automatic and high efficiency.

Select and use famous brand suppliers for motor and electrical equipment. Thermal/heat treatment frame to remove internal stress to keep longer service life.

Multi-control language for choosing: English, Chinese, Vietnam, Spain......

Advantage:

Carbon steel;

3 servo motors;

Dust & protect cover;

Language: Chinese, English, Spanish, Polish, Vietnamese, Portuguese and so on;

Electric equipment separated distribution by high and low voltage;

Laser cutting and heat treatment to avoid micro-shaking, longer service life;

Famous brand electric equipment: Schneider

High speed and stable working;

Safety labels for protecting method;

3. New Glue Station

1) Aluminum and stainless steel frame;

2) Stainless steel glue pot;

3) Glue heating function;

4) Glue recycle system and auto adding function;

5) Lubrication oil roller for inner paper strip;

6) One pair roller ( rubber roller and steel roller) for filming glue on paper.

7) 1 motor to drive glue roller;

8) Easy to adjust glue quantity by adjust the distance of two roller.

3. Paper Roller Bracket with connecting function

1) Help paper straw making machine no stop working.

2) Use out detection: When the paper roll is going to use out, the mechanism will cut the tail ends paper automatically to let paper connecting more successful.

3) Smaller dimension, easy delivery and moving to adjust paper feeding angle.

4) Construction simpleness. If paper break, no need to stop to route the paper up and down complicated.

5) Constant unwinding force for the paper rolls, to let paper feeding more smoothly.

6) Our own patent for this connecting mechanism, not copy from others, especially European brands, so no patent problem.

4. Conveyor & Collector

Pick up the straws automatically and row them tidily at the container.

Speed and height controllable.

If you have any enquiry about quotation or cooperation,please feel free to email us at gdxs03@chinagaoda.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.